Teralytic is a US-based precision agriculture firm creating a connected hardware and software platform to improve a farm’s yield by monitoring the growing conditions of the soil. By offering low-cost and easy to use sensor hardware, each platform packed with sophisticated soil sensing capabilities, a farmer managing dozens or thousands of acres can increase crop yields while using less water and less fertilizer. The network of hardware sensors makes the soil data available to a farmer's mobile device or laptop in nearly real time by using an efficient and robust wireless technology to transmit data to a central hub.

In this project, Tomorrow Lab helped to rapidly translate the technical ambition of the client into a concise list of features, functional proof-of-concept breadboard, and visualized product design. Using the proof-of-concept as our guide, we collected baseline data in our lab to meet benchmark functionality requirements, as well as vet the product design for ergonomic, aesthetic, and manufacturability concerns. This work laid the foundation for future product development and engineering for mass production.

Product Strategy

Industrial Design

Product Architecture

Electrical Engineering

In-lab Field Testing

Prototyping

The overall goal of this phase of work was to develop a path to an affordable, manufacturable, reasonably accurate, and precise instrument cluster allowing measurement of these seven soil parameters:

While the future vision of the product include wireless transmission of the collected data to a hub located in the farm, the proof-of-concept sensors we developed acquire data through a local computer connection. In doing so, we simplified the development process and focused on the most novel and challenging aspect: the sensors themselves.

As part of the research, we conducted a component sourcing exercise that included researching affordable or custom engineered sensors, as well as high-end instruments to benchmark the more affordable ones.

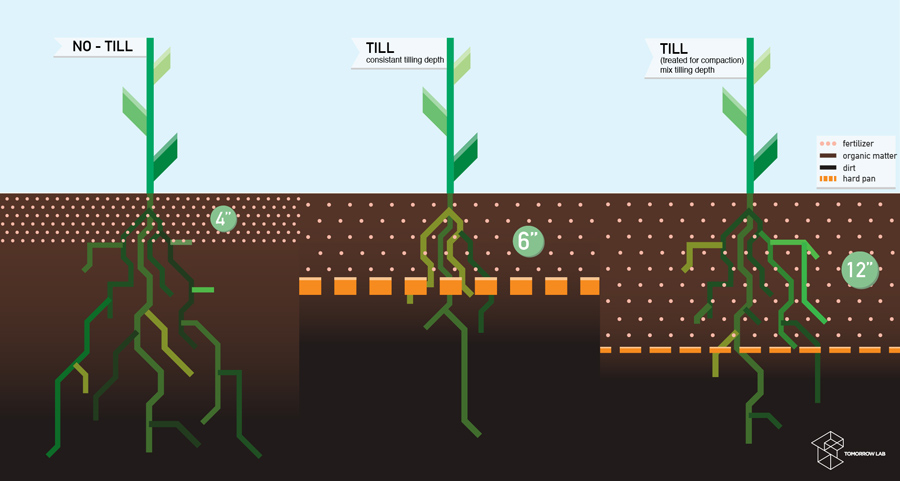

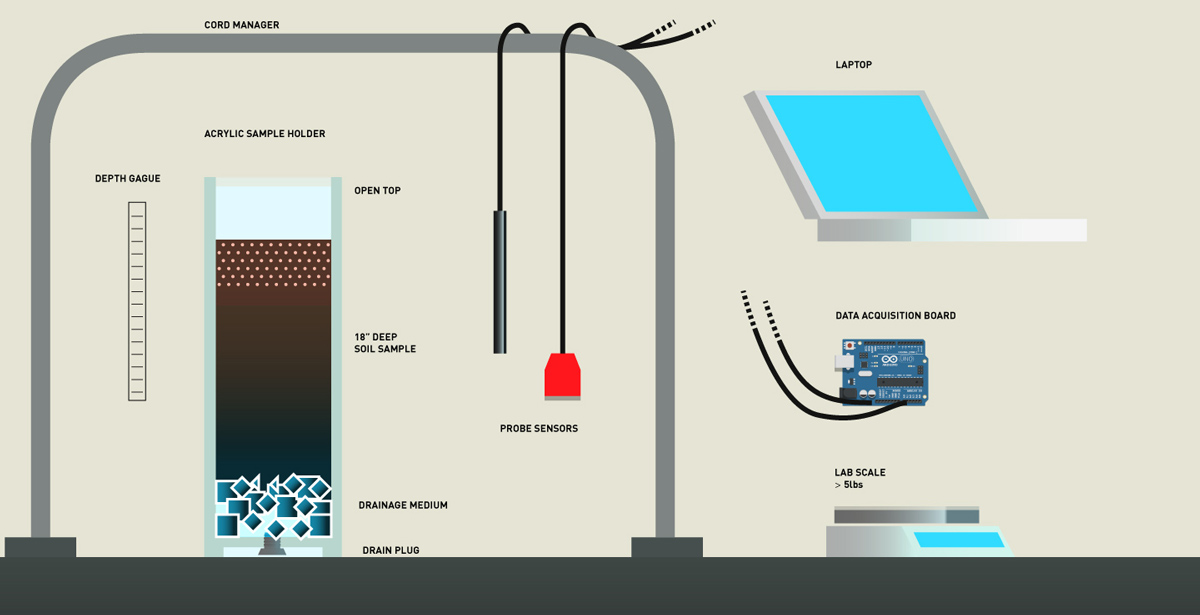

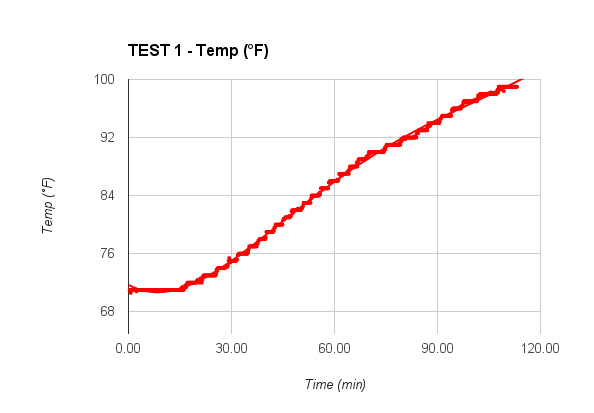

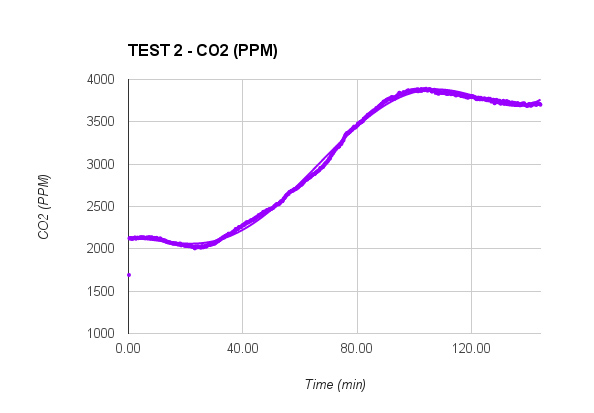

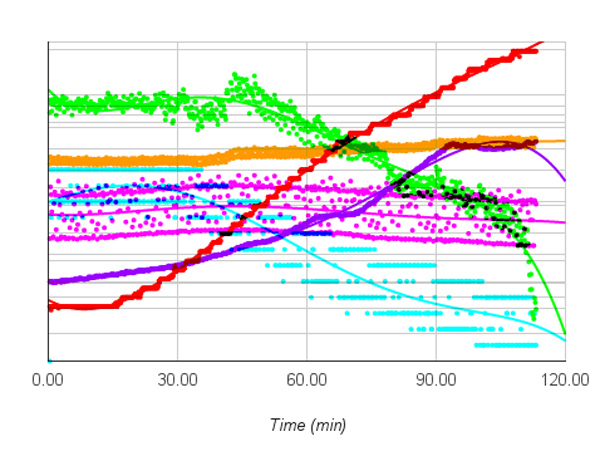

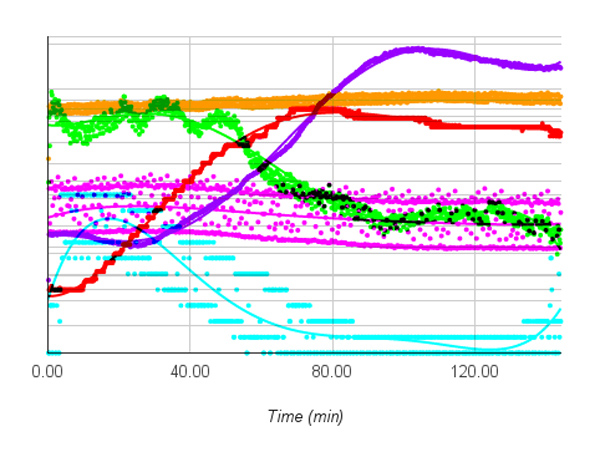

One of the first steps in creating a viable sensor product is to build a test apparatus and establish a test procedure in order to validate the sensor. For this project, we created a test rig holding a variety of 24” tall columns of soil. Each column housed different soil types (sandy, tropical, etc.) with and without fertilizer amendments for testing. More importantly, the columns also allowed manipulation of the seven soil parameters listed above. For example, to test temperature modulation, we used heating sources to raise the temperature of the soil column and record data. For moisture modulation testing, we first dehydrated the soil then introduced water content to rehydrate the soil and recording the data.

We wrote baseline firmware to log the gathered data from the instruments in the test rig. We then compared this data to other data gathered from the high-end benchmark instruments in order to establish accuracy and precision performance.

For these in-soil sensors, physical embodiments and housings of the sensors are critical to proper sensor performance and robustness over time. Both academic papers and hands-on prototyping led us to uncover a set of physical forms for each sensor type, which later informed the product architecture.

Additionally, we created an electrical schematic and electronic bill of materials (BOM) for the sensors to outline the critical components required in the product, to allow us to track the predicted cost of goods once in production.

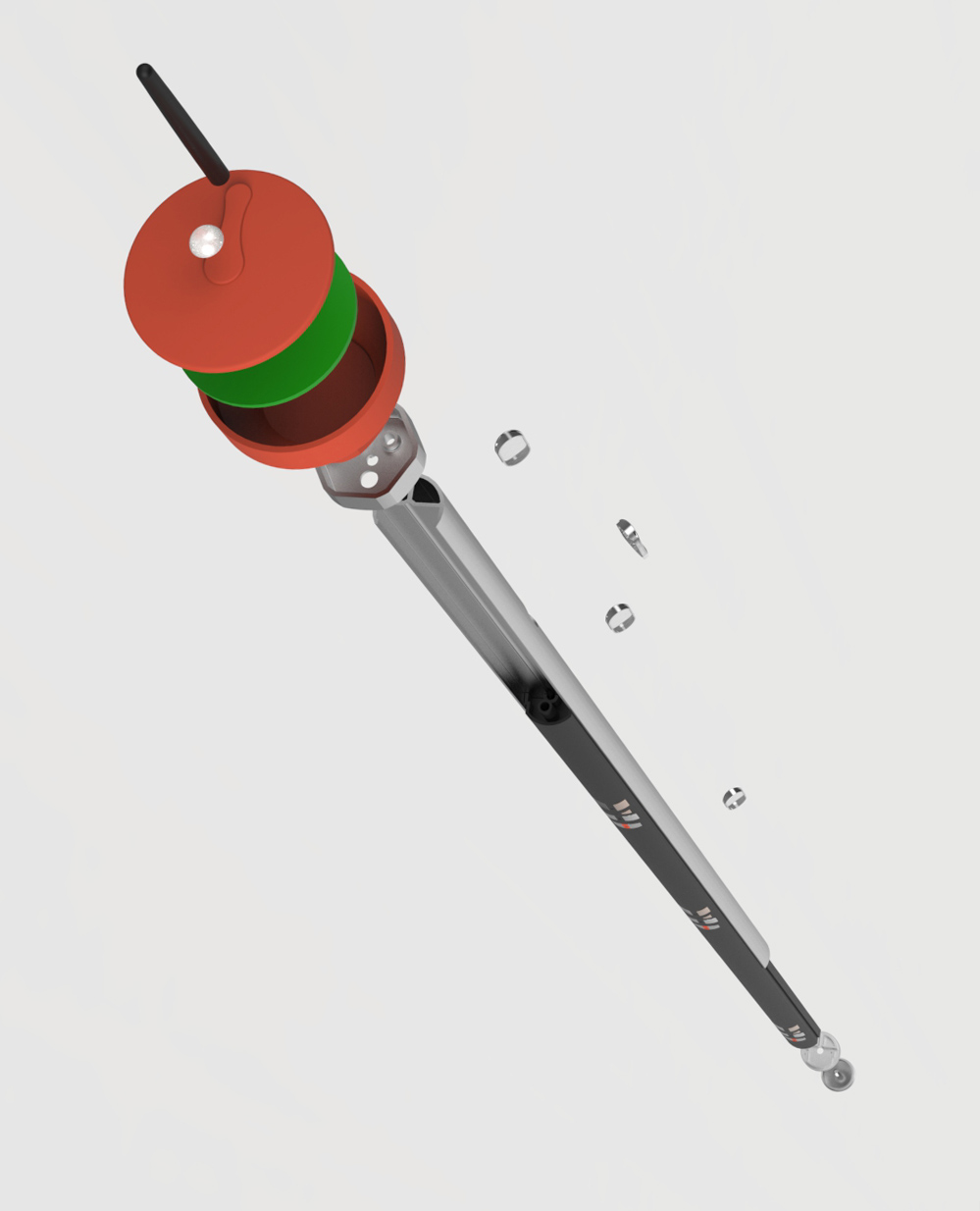

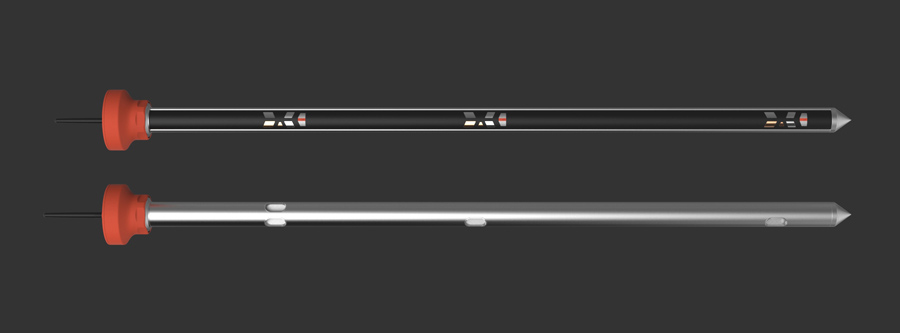

The product was divided into two main parts: 1) a ‘head’ to sit above ground and house higher cost components such as the wireless technology, and 2) a ‘shaft’ to be embedded in the ground making contact with the soil and house less expensive sensors. Through this design, the shaft offers several measuring points below the soil's surface to provide multiple, redundant measuring depths.

Taking a queue from available manual soil samplers, we imagined a handle with foot step to accomplish placement of the shaft in the soil followed by attachment of the head unit once placed.

Since the Teralytic sensor is designed to appeal to corporate and big agricultural customers as an industrial farming tool, we took a rugged approach with the design. Since the device seldom requires interaction with a person after installation, we did not include indicators in the design on the head.

With metals and neutral colored plastics throughout, we utilized bright orange pieces to indicate important touch points to the user.