RaceYa uses customizable, radio-controlled race cars to teach kids about science and help them design the cars of the future. RaceYa approached Tomorrow Lab with a kid-tested, proof of concept car with the desire to create the next version to be a modular, building block-like car that can easily be integrated into a education curriculum. This scope of work included creating a final prototype to be shown to potential investors.

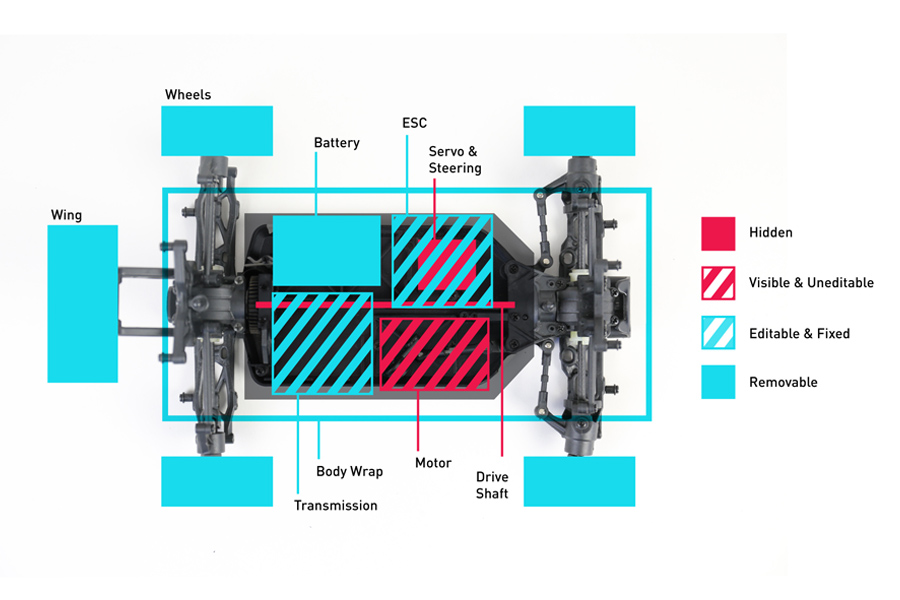

With this in mind, we developed a design scheme that included a forward-thinking strategy for the specific component categories to focus on Science, Technology, Engineering, and Math (STEM) through various car assemblies. Through our process, we developed a modular car platform with visual recognition, allowing modifiable placement of battery, motor, wheels, sensor, as well as a flexible body wrap and mounting points for that wrap. All fasteners were required to be removable, kid friendly, and thumb-tightenable.

Electrical Engineering

Mechanical Engineering

Industrial Design

Prototyping

Strategy

Branding & Logo Design

Tomorrow Lab and RaceYa collaborated to develop a feature strategy that satisfied a kid’s need to play and a parent’s need for that play to be educational. We chose the following six elements to focus on because they enabled a large number of play-based curriculums with immediately noticeable effects when varied: Batteries, Gear Ratios, Weights and Body Wraps, Wheels and Tread, Suspension, Electronic Stability Control (ESC).

Using our 3D printer, we then physically prototyped each element multiple times to test its feasibility and learn about user interactions. For example, the knobs for changing wheels or shocks gradually evolved from small round discs into small triangles best suited for kids hands. A belt pulley system, tensioned by a cam-action protective lid, emerged as the prime choice, because it effectively communicated how gear ratios worked, yet still shielded the user from moving parts.

Once all six elements were separately prototyped, we looked into considerations about how they might integrate into a complete car. Borrowing inspiration from other educational products like littleBits, we adopted a color-coordinated zone strategy, both to differentiate the functions of modular elements, as well as open up playing branding opportunities.

Instead of designing the entire car from scratch, RaceYa partnered with a toy manufacturer to use their existing products as a platform to build upon. The RaceYa car would be designed as a drop-in assembly that attaches to an existing chassis and interfaces with drivetrain components. The assembly could then be upgraded in the future to become a fully standalone car. Although this engineering strategy bypasses many technical problems, like designing complex differential gearboxes, it comes with the distinct challenge of sizing all parts to fit within the physical constraints of an existing product.

In order to combine all six enabling features into one drop-in assembly, we first conducted a thorough teardown of a manufacturer supplied car.

By reverse engineering the car in Solidworks, we were able to see critical dimensions, possible mounting points, and areas not worth modifying. The main drive gear, which transmits power to the drive shaft, was fixed on the chassis and subsequently drove the placement and sizing of all belt transmission components. Because of the expected complexity of our design, we built an auto-updating CAD assembly to ensure proper gear meshing and easy placement of other design features, like the battery and ESC area. This also enabled us to conduct interference checks to examine the physical dynamics of the movings parts.

The contours and colors for the car were designed to have a happy, playful feel, and to match the brand. We gave modular components a design language that spoke to their physical interactions to be more intuitive for the kids building the cars. For example, the undercut on the transmission cover acts as a finger groove and conveys lifting, whereas the hump on the battery implies pulling.

The final versions of the car were assembled in-house from 3D printed and machined parts, as well as custom milled PCBs (on the Other Mill), as well as cut plastic body wraps.

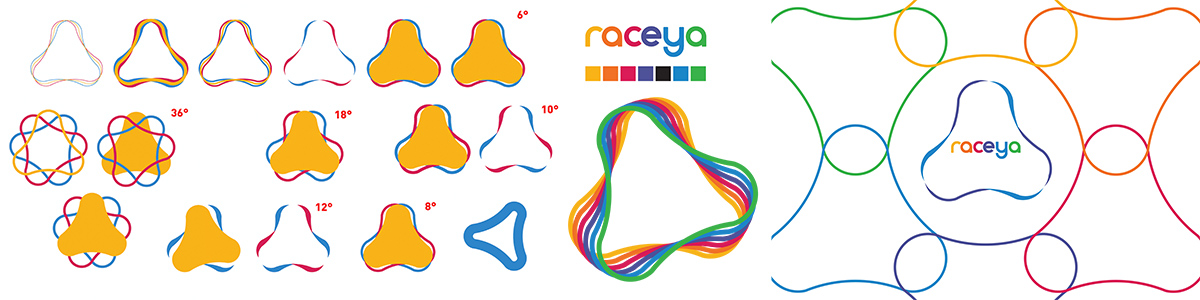

The concept of “learning by doing” is core to the RaceYa brand. In updating the brand identity we wanted to focus on playfulness, education, and motion. We kept the vibrant colors and wordmark of the original brand. Moving away from the black turnkey, we wanted to focus on a form that children would be more familiar with and would be reinforced by the product.