Along with the WayCount, our work for Social Bicycles, and the Buca Boot, the Hammerhead navigation device adds to our line-up of great products for bicyclists.

Hammerhead came to Tomorrow Lab looking to fulfill their vision of creating a smart, safe, Bluetooth-connected, hands-free bicycle navigation display device. After a successful crowdfunding campaign, and a position in the 2014 RG/A Accelerator program, the Hammerhead team had their form factor clearly mapped out and a few prototypes. Tomorrow Lab took on the task of fine-tuning the industrial design, electronics, and mechanical engineering of the mount and housing.

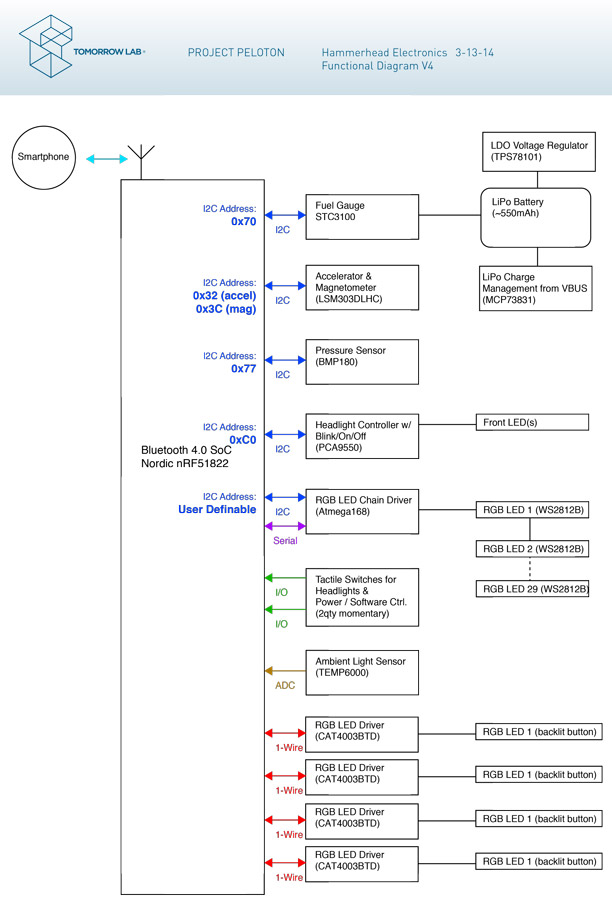

With the bulk of the design complete prior to onboarding Tomorrow Lab, the biggest challenge came in designing for manufacture including meeting the specific housing requirements and material selections. With an app-based platform leveraging Bluetooth 4.0 and location services, it had to stay connected with the phone, ensuring the whole ecosystem keeps cyclists on track.

Images courtesy of Hammerhead and Tomorrow Lab.

Mechanical Engineering

Industrial Design

Design for Manufacture

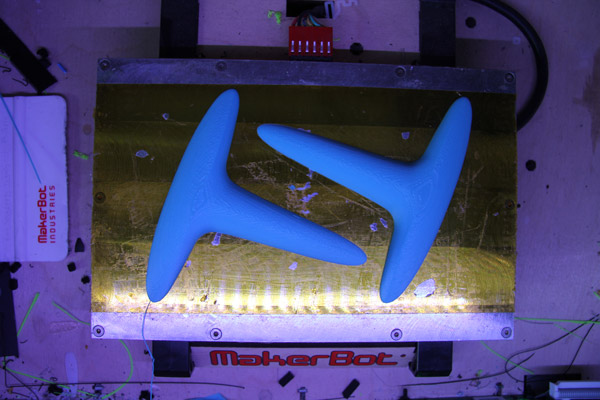

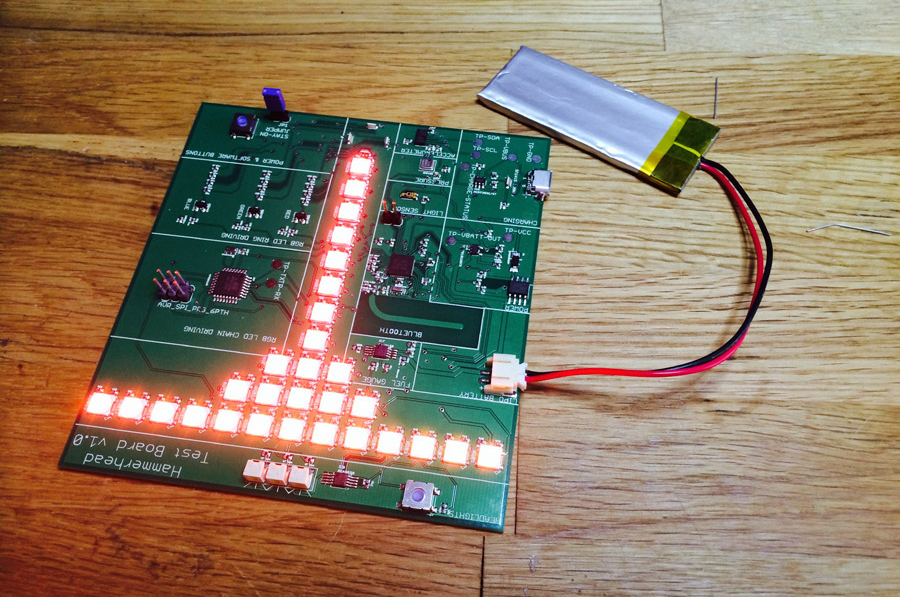

Prototyping

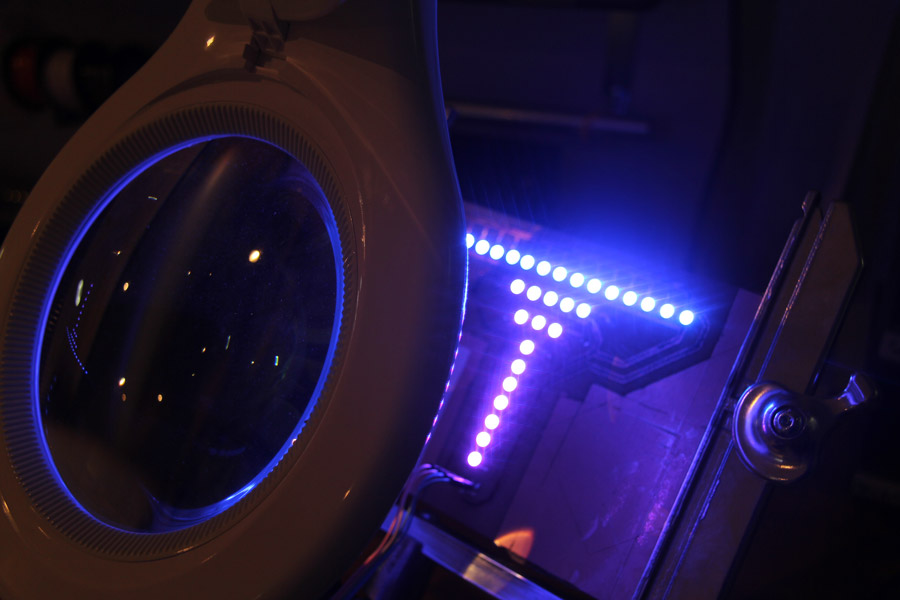

When working with a connected device, it is important to keep the software and hardware teams close. While the physical form factor needed fewer design changes, fitting the components within that shape was critical. With the help of Hammerhead, we were able to build a LED light pattern that would fit perfectly into the circuit and housing, as well as integrate fully into the operating system. All of these details are key to preparing for the final prototype before heading into manufacturing. Hammerhead worked with Tomorrow Lab to apply the mantra of learn, make, test, break to ensure that each prototype phase would get us one step closer to a market-ready product and into the hands of the campaign backers, and those who have purchased the product since.

To ensure the factory understood every detail, and that Hammerhead knew how to work with these often minute changes, Tomorrow Lab not only offered manufacturing support, but also accompanied Hammerhead to China to have feet on the ground at the factory.

The Hammerhead device uses a ‘T’-shaped RGB LED interface as its main communication method to the user. This interface, when combined with Hammerhead's software, takes complicated directional instructions and makes them simple. It affords a more safe and enjoyable way to receive navigation directions while riding your bike. Through the app, it also provides an online community of routes and riders.

Other features include a high-lumen headlamp for visibility and safety, backlit main button, and a water-resistant USB port for battery charging.

We created a clever ‘soft-key kill switch’ power circuit design that extends the battery life to the maximum extent possible while the device is not in use. The main IC is able to completely disconnect the circuit from power draw when powering down, which is even more energy conservative than a low-power sleep state.

Because the device is intended to be used both on and off road, at night, and in all weather conditions, Tomorrow Lab thoroughly researched appropriate materials and housing components. The device had to be waterproof, shake-resistant, sturdy, and maintain both a constant connection, and a high battery life to feed the LEDs for consistent safety and security.

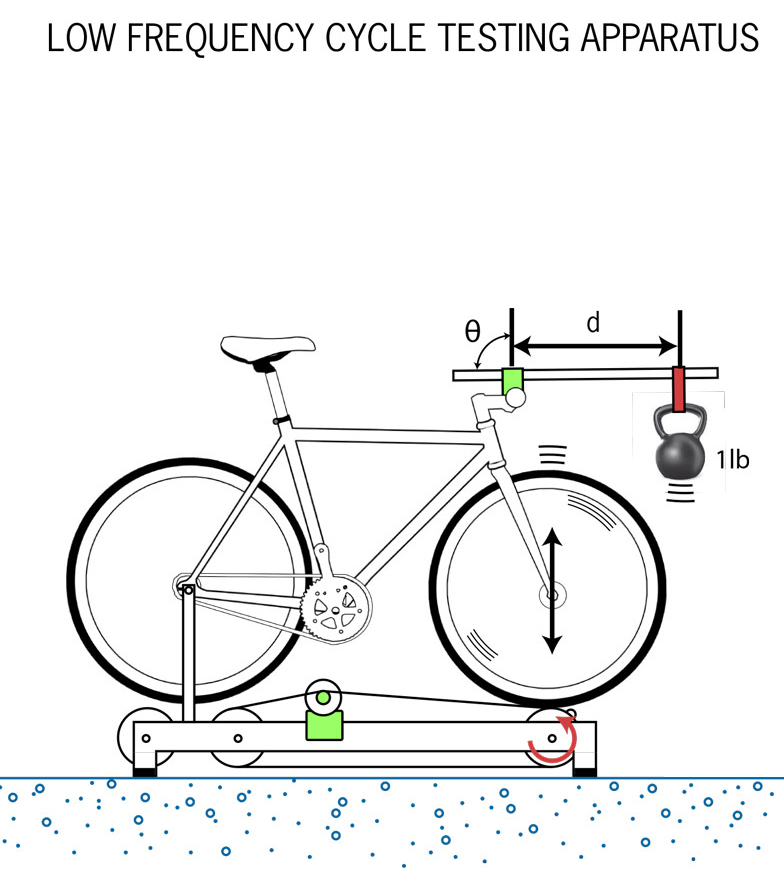

With these requirements in mind, as well as keeping the existing shape and form factor, we set out to apply our manufacturing knowledge to the next iteration of the design. In order to design a bracket that would mount the device securely to the handlebars of a bicycle with little resonance, we built a testing rig to monitor the “shake factor” of day-to-day riding. We tested two designs of an adjustable handlebar mount to compare their maximum resistance to torque under cyclical loading.

We designed a testing rig around a full-sized bicycle in order to closely simulate the low frequency vibrations created when cycling over uneven pavement. We then conducted various simulations using a weighted mass suspended from a cantilevered beam attached to the bicycle. Using the rig, we were able to benchmark the torque resistance of competitive samples. We used the same system to verify and compare our new designs for the Hammerhead mount.

By combining research of existing bracket choices for lights, bells, cameras, Garmins, and the like, and the test results of the rig, we determined the kinds of brackets that would ensure stability and designed a visually appealing bracket for the tail of the device.